How to make the normal Beacon¶

Low Profile USB Cable

With the introduction of the Low Profile assembly option, there are now two types of cable. They are NOT compatible, and using the wrong type may damage your Beacon. When you order a kit, the normal cable is included by default. This works for right angle and normal assembly. The low profile cable is different and available on request. If you have any concerns, ordered a kit, or would like to double check, see the USB Cables section.

Step 1 - Tools¶

To create a right angle Beacon, you will need the following tools:

- Soldering Iron

- Solder

- Flux (optional)

- Wire cuter

Step 2 - Connectors¶

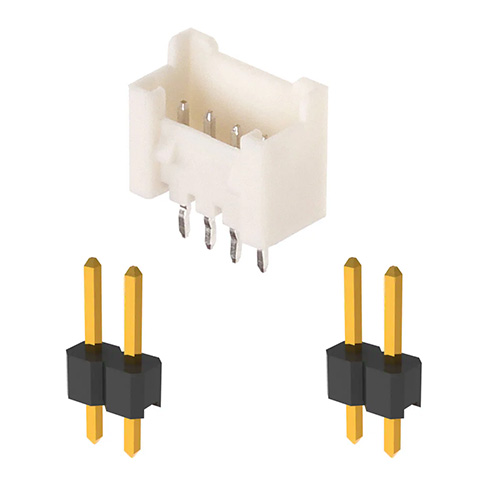

You also need the following pins and connector (which you should have received):

Step 3 - Print models¶

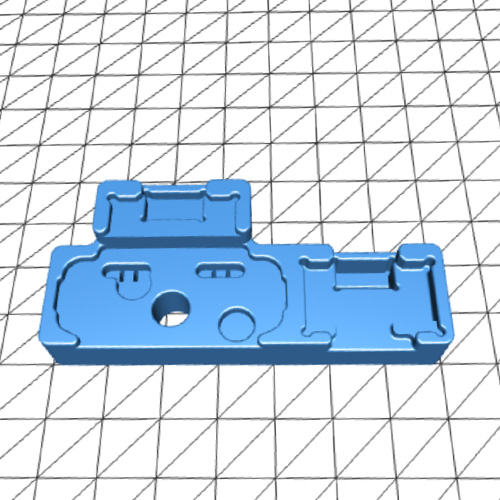

You will need to 3D print a CAD model which will provide the foundation to solder the Beacon correctly.

Step 4 - Pin placement¶

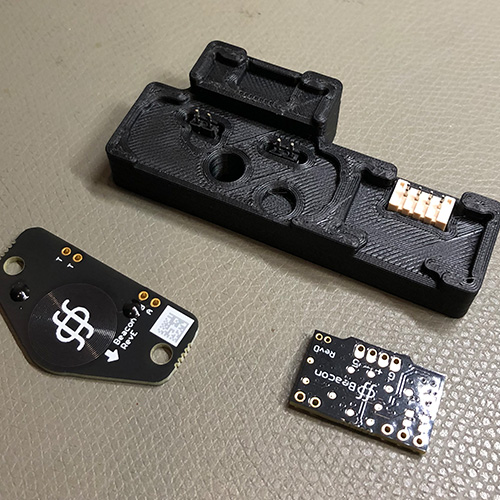

Place the connector and pin into your 3D foundation model as follows:

Step 5 - PCB placement¶

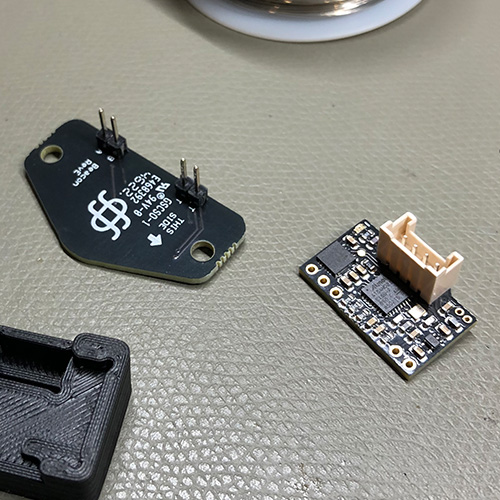

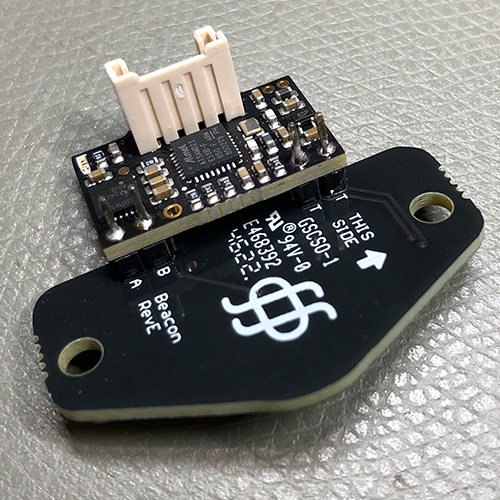

Place the amplifier PCB (the small rectangular one) and the sensor PCB in the foundation as follows:

Step 6 - Solder pins¶

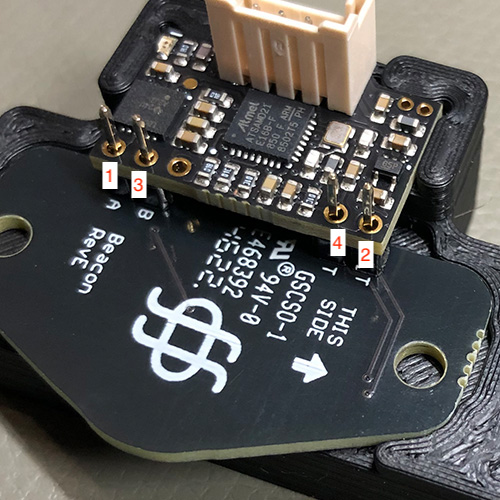

Solder the pins in the order shown:

Step 7 - Inspect¶

Inspect the results so far.

Step 8 - PCB placement¶

Place the amplifier PCB (the small rectangular one) and the sensor PCB in the foundation as follows:

Step 9 - Solder pins¶

Solder the pins in the order shown:

Step 10 - Inspection¶

Inspect the results.

Step 11 - Trim pins¶

Use your wire cutters to trim down any of the pins your soldered.